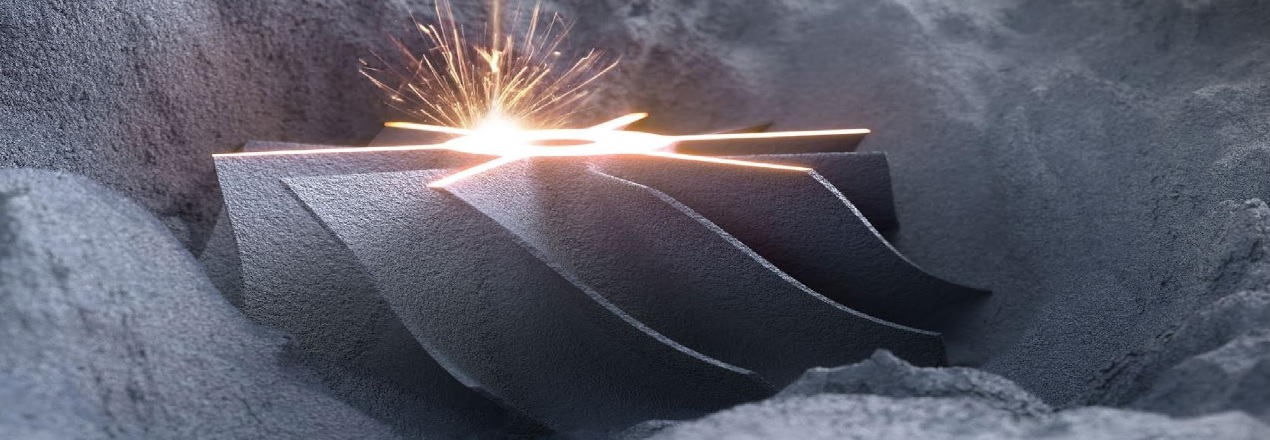

Additive manufacturing or three-dimensional (3D) printing will have revolutionary impact on the manufacturing processes as it offers significant advantages over the conventional manufacturing techniques and technologies. While rapid prototyping allows fast and cost-effective mass-production, additive manufacturing enables customized and indiviualized products right on demand.

The main idea behind the technology of additive manufacturing is to create physical objects out of plastic, metalic or ceramic-based materials from digital models. Its key feature is layer-by-layer build-up of parts. The process starts from raw materials with almost no specific shape and therefore no special component tools and moulds are required.

FARPACO is establishing a R&D divison for additive manufacturing. The mission is to focus on implementation of the techniques, processes and products directly into the industry while trying to be innovative.

To accelerate the obtain of knowledge and know-how related to the technology of additive manufacturing in the region, FARPACO is teaming up closely with universities and research centers of excellence as well as technology owners all around the world. The joint research & development projects are targeted on the products for which high demands and interests are expected from the key industries of the country such as oil & gas, automobile, mining and etc.